Productions with Bakelized Canvas

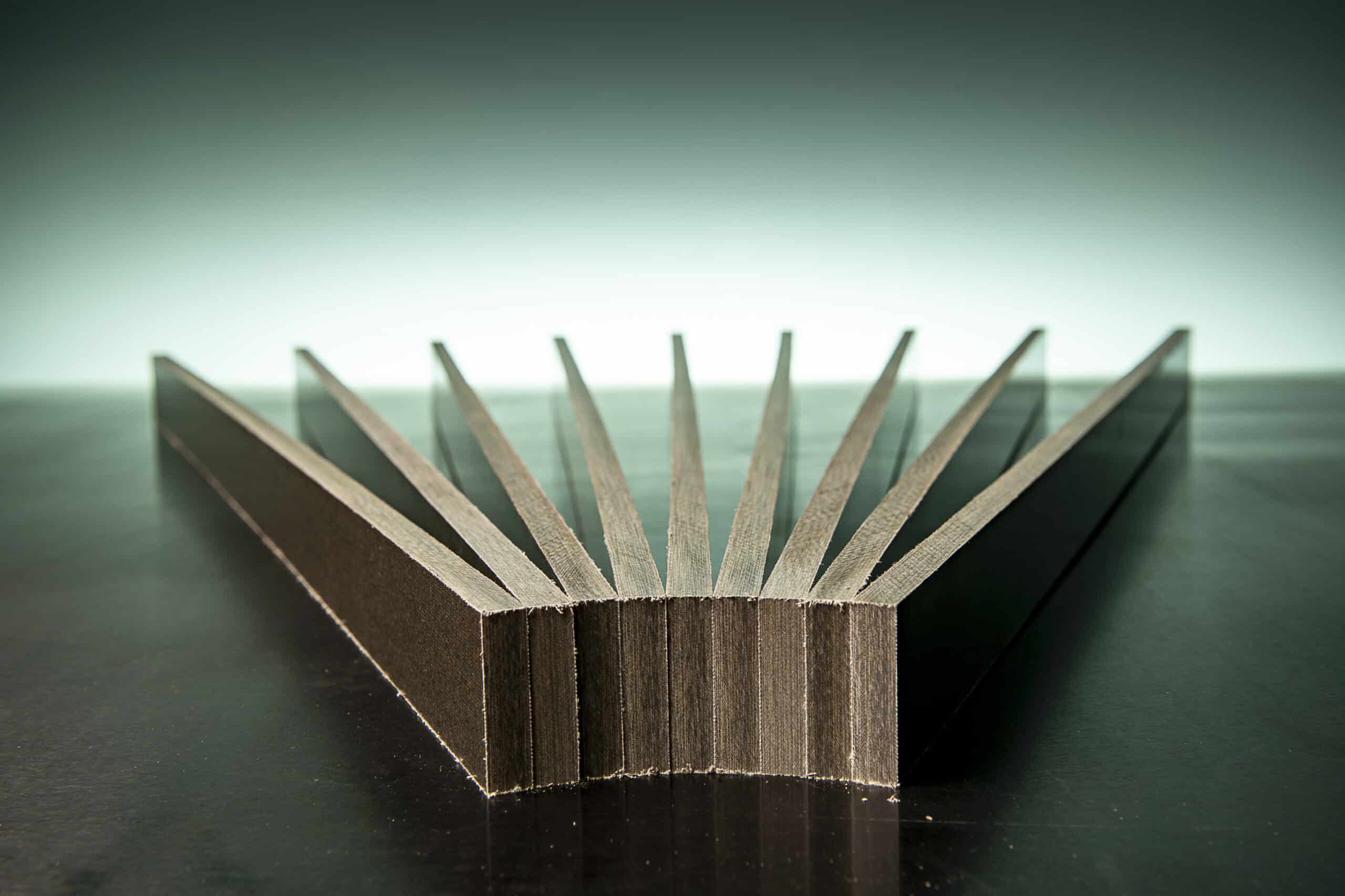

Bakelized canvas is a composite laminate made of phenolic resin and cotton fabric. Bakelite is a thermosetting polymer with which the layers of canvas are impregnated, which polymerize when hot pressed, producing reinforced Bakelite. Bakelized canvas is also known by its trade name Celeron.

This material falls into thermal class E, with an insulation temperature of 120° C. In the event of open flames it burns slowly and is classified as self-extinguishing class HB by the UL 94 standard, which defines the tests and flammability classes of plastic materials and composites. A ductile material, suitable for numerous uses, also thanks to its self-lubricating quality.